IET Lead Free Wave Solder Machine MS•450

Manufactured by JT Electronic Equipment CO., LTD

* About JT

• Dimensions

• Specification Sheet

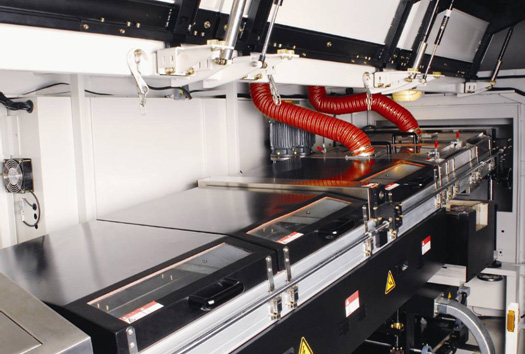

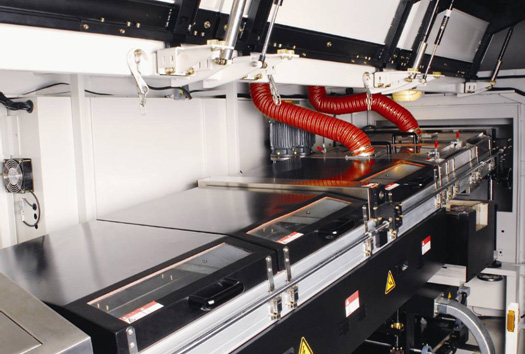

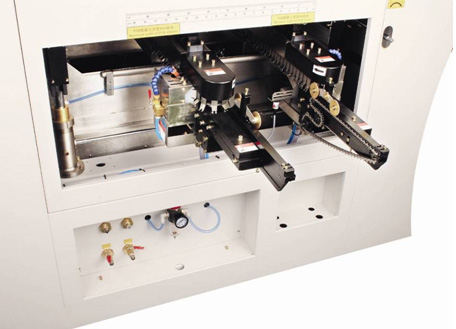

Conveyor System:

Conveyor System: Titanium center support for larger and panelized

PCBs. Flexible titanium fingers secure the PCB more reliably.

Easily replaced if needed, reducing maintenance and down time.

Integrated finger cleaning system with recirculating solvent

reduces PCB contamination.

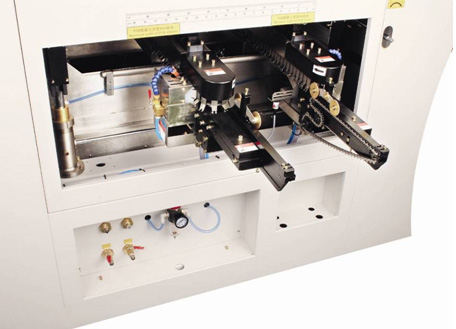

Automatic Motorized Spray Fluxer:

Automatic Motorized Spray Fluxer: Spray nozzle is

Servo Motor driven with speed and spray control.

Provides consistent and uniform application of flux across

any PCB at any conveyor speed. Automatically switches

on and off when PCB is detected.

Three Convection Preheating Zones

Three Convection Preheating Zones Optimum

preheating profile can be easily obtained. Effectively

improves wetting ability. This is a key requirement for larger

boards, larger components and for the higher temperatures

required for lead• free applications.

Inverter with closed loop control system manages the stability

and accuracy of the conveyor speed. Board guides synchronized

with conveyor system ensure boards enter smoothly into wave

solder machine.

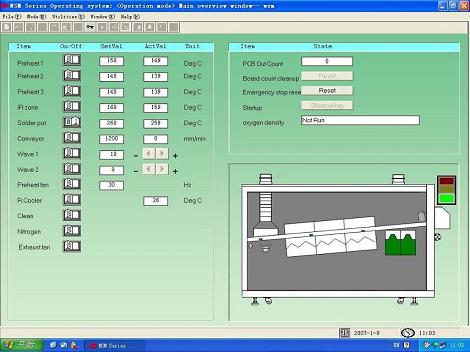

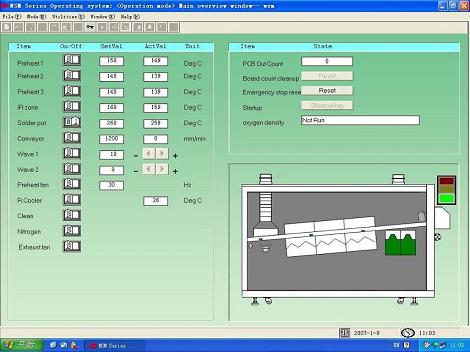

Windows XP:

Windows XP: Displays and records temperature control curves.

Logs and prints production statistics. Automatically stores

the operation and status of machine. Displays alarms in

main window.

|

IR Boost Heat between the last pre•heater and the solder

wave eliminates the loss of heat prior to soldering.

This is a key feature and requirement for the high temperatures

used in lead•free soldering.

|

|

Anti•corrosion 1500 lb. capacity Titanium Alloy Solder Pot

for lead•free solder. Automatic standby laminar and turbulent

waves (within 30mm of each other) provide optimum temperature

stability and reduced dross generation.

|

|

Motorized Solder Pot: Motorized drive system raises and lowers

the solder pot as well as rolls the solder pot in and out for

ease of maintenance.

|

|